Home Base

AS SEEN IN

Manufacturing locally means less of an environmental impact, full transparency and true ethical manufacturing.

The workers involved in making our apparel are paid wages that meet or exceed California minimum wage. Our manufacturers have socially responsible operations, with fair, safe and healthy working conditions.

Since we are manufacturing locally it allows us to visit the facilities we use and meet the workers who make BxB garments face to face. It’s important to us to know exactly how our garments are made and be confident in the way they are made. We’d like to share that process with you.

THE PROCESS

01 CONTRUCTION

It starts with yarn that gets milled and knitted into high quality fabric in local facilities. Then this fabric gets cut based on a pattern. The pattern pieces are sewn together creating a functional garment.

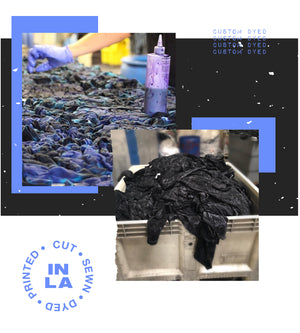

02 GARMENT DYE

Once the tees have been constructed they are sent to our dye house. Using low impact dyes, the tees are dyed with a custom color, wash or tie dye treatment that makes each one a truly unique piece. Garment dying creates a soft hand feel and are also pre-shrunk for a better fit.

03 SCREEN PRINTING

After the tees have been dyed they head over to our female owned screen printer at Deluxe Screen Printing that carefully prints each garment by hand using superior vegan eco friendly inks.

04 FINISHING

The final stage of this process includes adding any of the following when necessary: special labels, hang tags, cutting shirts into crop tops and folding to be prepared for shipping in our eco-friendly packaging from Eco-Enclose.